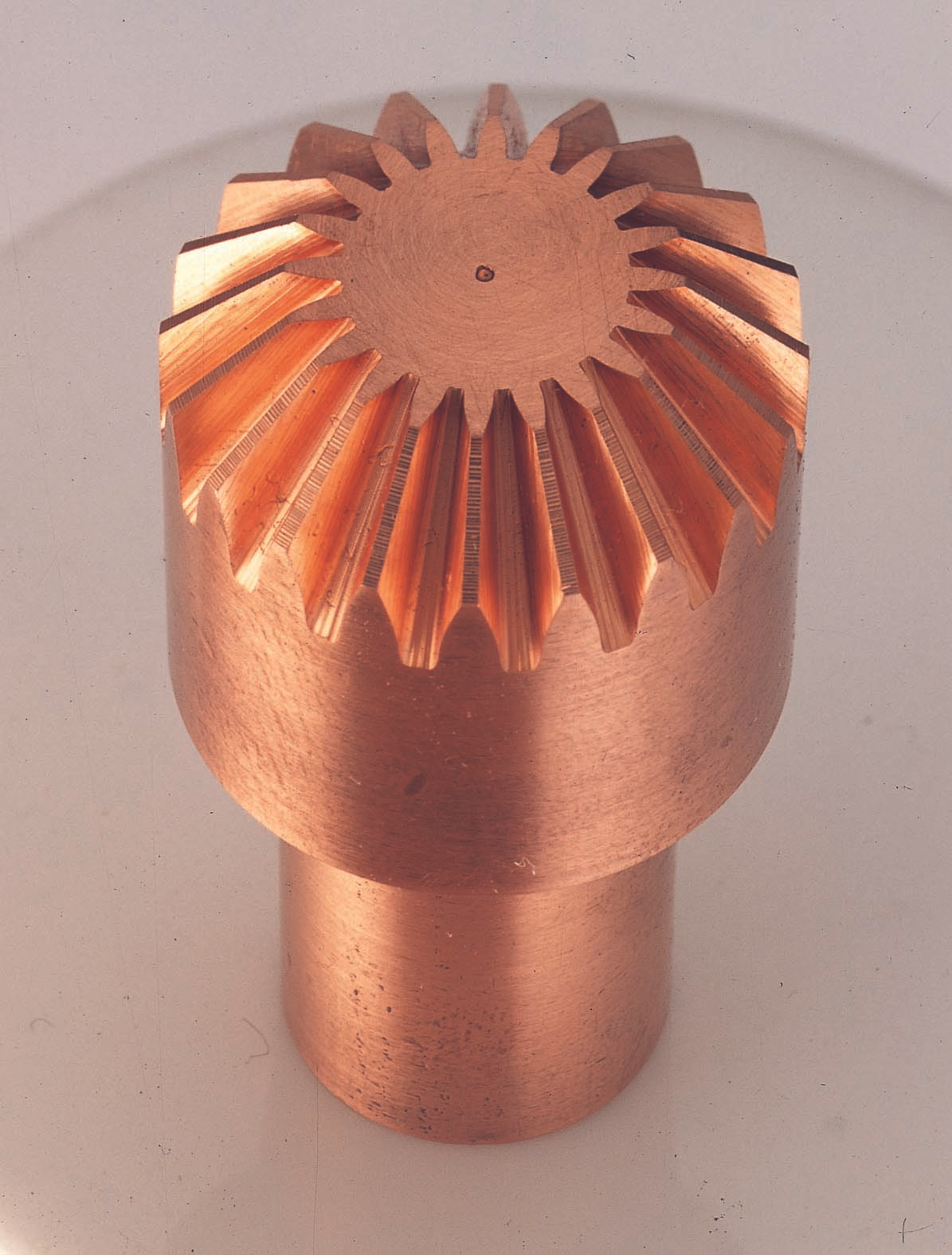

傘齒電極採用Gleason 710,切齒後確實做到齒輪接觸檢測,能使產品達到良好狀態。 齒輪的主要切削製造程序為原料à鍛胚à粗切削à熱處理&agr

齒輪的主要切削製造程序為原料à鍛胚à粗切削à

The Chuan Fu Gear Co., Ltd. was established in 1989; in the beginning, we provided gear machining and design service; since domestic mold vendors have to import precise gear electrodes and advanced design overseas, which would cause inconvenience in communication, price up and long delivery schedule; therefore, we have devoted into the gear electrode developing market to meet vendor's demanding locally.

So far main vendor's in Taiwan all have been purchasing products from us. In 2000, we' ve changed company title to"MODEL MARK CO., LTD."and formally involved the mold field.

To elevate the machining precision and speed of ordinary gears, we have introduced the advanced

P60 and P90G CNC high-speed hobbing machine made by Gleason(USA) to perform high-speed & high-precision gear production process.

P60 & P90G can machine all sorts of precise electrodes, standard gears, worms, worm gears and special gears; except performing high machining efficiency and precision, these hobbing machines also can make any angle's rotation, unlimited helical angle machining of helical gears, and hard-surface cutting and grinding; on particular the teeth profile grinding of powder metallurgic gears after hardening process. This providing customer the best quality.

Mr. Chui-Bin Lee, 12 years experience in ITRI (Hsinchu) as the professional technician of gear design & production; during it, he was sent to Gleason Co. in USA attending advanced training program.

By collecting both theory and skill, Mr. Lee is a national treasure in Taiwan. He has both design and machining experience to the cylinder gear, bevel gear, worm gear and other special gears of wide variety for many years; glad to accept the challenge of machining special gears and help solving for any problem in gear field

To electrode products, we hold the idea that our products are cheaper and better than foreign ones, convenient to communicate and we help client solving related gear problems; thus our client can have confidence receiving mold orders under our support. Both parties would get benefit on the business.

To ordinary gears, we hold the idea of "Elevation quality, fast delivery and reasonable price", facilitating to the promotion of gear machining market; and we apply advanced equipment to get the advantage in market competition.

To design work, we tend to shorten client's product developing time and eliminate time waste; making our design able to get production cost down, elevate competition capability and easier to get orders

Since the traditional industry vendors in Taiwan now are emigrating abroad; thus, to accommodate to current Taiwan industry status, we are planning to get involved in the gear production with high skill and precision difficulty and develop aviation gear machining process; we anticipate elevating gear machining quality level in Taiwan and step forward to the goal of sustainable operation.